Lihlahisoa

Nuts Almonds Walnuts Cashews Peanuts Plastic Bottle Glass Jar Ho Tlatsa le ho Paka Mochini o nang le Mochini oa ho Ngola

Tlhaloso ea Sehlahisoa

mochini o tlatsang

Haholo-holo e entsoe ka ho hlopha botlolo + ho tlatsa + capping + labeling + cartoning le likarolo tse ling. Mohala oohle o laoloa ke PLC, skrine ea ho ama e fetola liphetoho tsohle tsa parameter, ha ho hlokahale hore u fane ka matla mochine o mong le o mong ka thoko.

| ZH-JR | ZH-JR |

| Ka bophara (mm) | 20-300 |

| Na bophahamo (mm) | 30-300 |

| Lebelo le Leholo la ho Tlatsa | 55can/min |

| Boemo No | 8 kapa 12 Tobetsa |

| Khetho | Sebopeho/Sebopeho sa ho sisinyeha |

| Parameter ea matla | 220V 50160HZ 2000W |

| Bophahamo ba Sephuthelo (mm) | 1800L*900W*1650H |

| Boima ba 'mele (kg) | 300 |

Kopo

lijo-thollo, thupa, selae, globose, lihlahisoa tsa sebopeho se sa tloaelehang joalo ka lipompong, chokolete, jelly, pasta, peo ea mahapu, makotomane, pistachios,

lialmonde, li-cashews, linate, linaoa tsa kofi, li-chips le lijo tse ling tsa boikhathollo, morara o omisitsoeng, plum, lijo-thollo, lijo tsa liphoofolo tse ruuoang lapeng, lijo tse ikhohomosang, litholoana, tse halikiloeng.

peo, hardware e nyenyane, joalo-joalo

lialmonde, li-cashews, linate, linaoa tsa kofi, li-chips le lijo tse ling tsa boikhathollo, morara o omisitsoeng, plum, lijo-thollo, lijo tsa liphoofolo tse ruuoang lapeng, lijo tse ikhohomosang, litholoana, tse halikiloeng.

peo, hardware e nyenyane, joalo-joalo

Libotlolo le linkho tsa boholo bo fapaneng

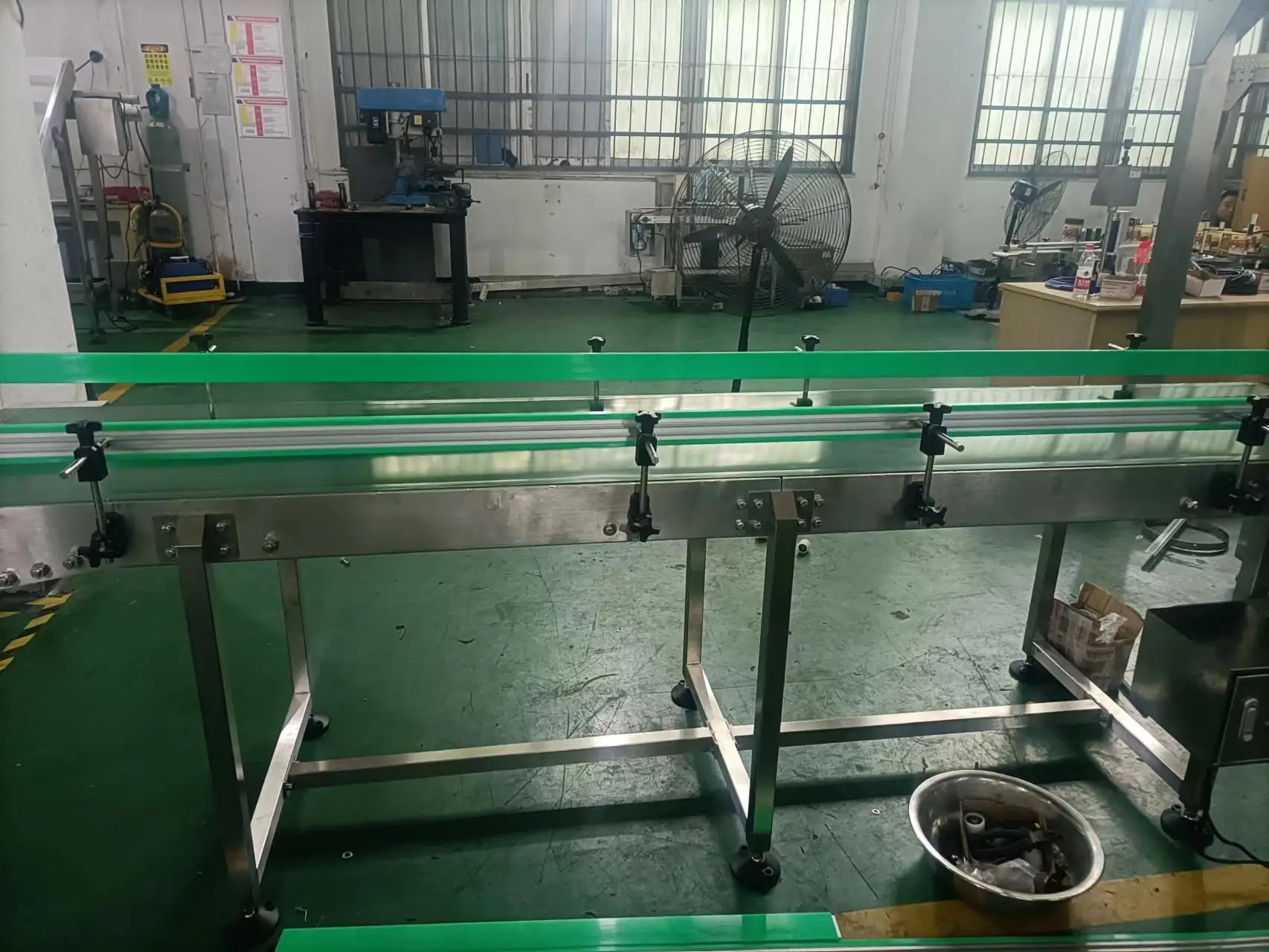

Mohlala oa Pontšo

Litšoantšo tse qaqileng

Hlophisa pokello ea libotlolo

Thepa e phahamisoa ke z sebopeho conveyor mme ho bonolo ho e hloekisa.

Khetho e ntle ka ho fetisisa bakeng sa indasteri ea meriana

Lihlahisoa tsa ho bekha tse ngata

7inch HMI, taolo ea MCU;

Tšehetso bakeng sa mechine eohle

Ho tsamaisa libotlolo, makotikoti, joalo-joalo.

Ho tlatsa lisebelisoa tse lekantsoeng ka bongata.

304SS Frame, e nang le liteishene tse 12, bophara ba hopper bo ka etsoa ho latela makotikoti.

Mosebetsi o ka Sehloohong

1. Lebelo le Eketsehileng: E na le mochine o tlatsang rotary ho matlafatsa lebelo la tlhahiso.

2. Precision Capping: E na le mokhoa oa ho roala liroboto bakeng sa capping e nepahetseng le e tsitsitseng.

3. Katleho ea Mosebetsi: E fokotsa litlhoko tsa mosebetsi ka ho iketsetsa mokhoa oa ho etsa capping.

4. Ho nepahala ho Ntlafetseng: Ho netefatsa ho nepahala ho phahameng ho tlatsa le ho etsa capping.

5. Advanced Automation: E kenyelletsa theknoloji ea morao-rao bakeng sa ts'ebetso e sebetsang hantle le e tšepahalang.